Custom engraving on glass or crystal offers a timeless way to personalize items, with engravings that are permanent and resistant to dishwasher cleaning.

This method allows for the addition of text, numbers, or logos, making each piece unique and customized. The versatility of engraving extends to a wide range of items, including wine, beer, and champagne glasses, bottles, perfumes, and mirrors.

Whether for personal use or as a special gift, a glass or crystal engraving provides a lasting impression and a touch of elegance to any occasion.

Discover our glass engraving machines

Our engraving stations offer tailored solutions for various needs.

The M20 is perfect for small items like perfumes, offering in-store personalization. Gravotech provides an exhaustive jigs range for custom engraving.

Using an engraving gel increases the diamond tool lifetime and ensures a clean and smooth engraving result.

For larger products such as beer glasses and bottles, the M40 Gift and IS400 are ideal, featuring a rotary device for all-around engraving. The M40 Gift includes an automatic lubricant tank.

The WeLase™ is perfect for fast glass and crystal engraving on small products like perfumes.

With a 30W CO2 laser source, this glass engraving machine effortlessly engraves glass and crystal.

The F100 lens, a new optional lens that can be installed on a Welase CO2 machine, ensures seamless, high-quality engraving, reducing the risk of chipping and breaking, especially for filled logos or fonts.

Our laser tables are perfect for glasses and bottles, equipped with a rotary device for all-around engraving.

Powered by a 30W CO2 laser, they efficiently provide custom engravings on glass and crystal.

For optimal results, we recommend the following machine depending on your items:

Small CO2 laser engraver and cutter for personalization, signage and creative.

LS100

Medium CO2 or Fiber laser engraving and cutting machine for signage and small series.

LS100 EX

Large laser engraver and cutter that can do everything.

LS900

Laser tables lenses

Crystal & Glass engraving: laser or rotary

Glass laser engraving

Experience rapid and efficient glass personalization through laser engraving and increase your business margins. Glass laser engraving doesn’t damage or heat up the product content.

The result is a polished, frosted or sandblasting effect.

We recommend using various techniques to achieve optimal results:

- Utilizing wet paper, the most common method, which reduces surface temperature and prevents splinters.

- Leveraging the halftone mode on Gravostyle™ for our LS laser tables, which prevents overheating and splintering.

Enhance your glass and crystal engraving by adding color using gilding wax, available in gold or silver, for an elegant finishing touch to your products.

Advantages of glass laser engraving

Glass laser engraving offers the following benefits:

- Speed and silence: fast and quiet engraving processes, ideal for in-store personalization.

- High precision: achieve intricate designs effortlessly with laser beams as thin as 0.1mm, ensuring precision even with complex patterns. This enables detailed work, such as precisely filling in logos and text, and even engraving photos.

- Contactless engraving: ensure safety and the etched product integrity with contactless engraving, eliminating the need for jigs and minimizing the risk of damage.

- Versatility: a CO2 laser source allows to engrave not only glass but also various organic materials, eliminating the need for multiple machines.

Glass mechanical engraving

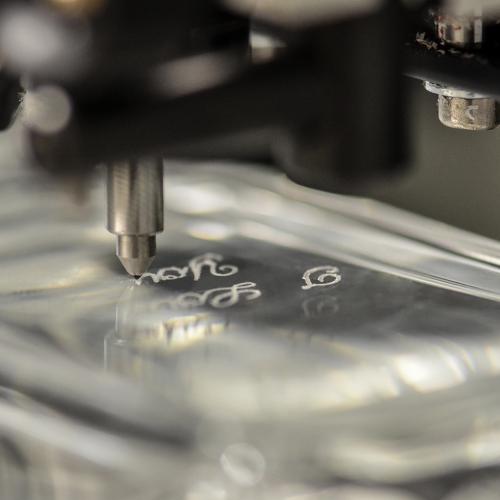

The glass mechanical engraving process ensures precision without the risk of product breakage, as machine pressure is meticulously adjusted.

Engraving gel is employed to prevent glass splinters and prolong the life of tools.

The resulting engraving is characterized by a white appearance, with grooves carved by a rotating diamond tip, making it perfect for stroke fonts and unfilled logos, achieving an authentic look.

Add color to your engravings using gilding wax, available in gold or silver, and add an elegant touch to your products.

Advantages of a rotary glass engraver

Using a rotary glass engraver offers the following benefits:

- Precision: achieve precise engravings with thin strokes, creating an elegant and visually pleasing result that reminds of handmade engravings.

- Enhanced results: incorporate gilding wax for a touch of color, enhancing the overall appearance and adding an extra layer of elegance.

- Versatility: mechanical engraving machines are capable of engraving various materials, eliminating the need for multiple machines and offering flexibility in your engraving projects.

Why choose glass engraving over other techniques

While many other glass personalization exist, glass and crystal engraving is:

- Timeless and heat resistant. Engraving ensures enduring personalization that withstands heat without deterioration.

- Clean and precise. Unlike techniques like sublimation or inkjet printing, engraving offers clean and precise personalization, even for small details.

- Durable. Other techniques may be susceptible to scratches or damage from dishwashers, while engraving maintains its integrity over time.

- An interactive experience. Offering engraving services in-store allows customers to witness the personalization process firsthand, creating magical and memorable moments that enhance their experience.

Our solutions match your glass engraving application

Bottle & glass personalization

Glass engraving elevates special events with personalized touches on bottles, evoking emotions through engraving.

Engrave glass and crystal items in-store, online, or during events. Achieve personalized engraving on bottles and glasses, including conical shapes, for a truly customized experience.

Perfume bottle & make-up container customization

Boost your margins and create in-store traffic with live product engraving.

Engrave all kind of products with various shapes, sizes and material, including flat and cylindrical items.

Our rotary device enables all-around engraving and placement flexibility to achieve truly customized results.

Personalización

Hazlo único, crea emociones

¿Es usted una marca de lujo o una marca internacional y desea desarrollar una experiencia de cliente exclusiva en tienda para sus clientes, en su sitio de comercio electrónico o durante un evento?

Gravotech le propone soluciones a medida que responderán a sus necesidades. Un jefe de proyecto dedicado le guiará a lo largo de toda la colaboración: discusión de los requisitos, realización de muestras en sus productos, selección de la tecnología de personalización más adecuada, despliegue de la solución y formación de los usuarios.